Y (2011), “Axial Flow Ventilation Fan Design Through Multi-Objective Optimization To Enhance Aerodynamics Performance”, Journal of Fluid Engineering, Transactions of the ASME, 133(10), 1-8 “Numerical Analysis Natural Frequency at Low Pressure Boiler Feed Pump PT PJB UP Gresik ”, Jurnal Teknik ITS, Vol. (2015) " Experimental Study of Effect Blade Setting Angle 30 and 60 with Flat Plate Profile in Working Characteristic Curve of Axial Fan 120 mm, Institute Technology of Sepuluh Nopember.īruce R.

al, "Selection and Design of an Axial Flow Fan ," Journal of Mechanical, Aerospace, Industrial, Mechatronic and Manufacturing, vol. (2020) “Analysis The Effect of Angle Stack and Airfoil Geometry NACA to The Performance of Axial Blade”, Politeknik Perkapalan Negeri Surabaya.ĭ Almazo, et. Performance enhancement of axial fan blade through multi-objective optimization techniques, Journal of Mechanical Science and Technology. The simulation results using Ansys Modal, show that there is a natural frequency of 287.8 Hz and the simulation results of Ansys Harmonic Response obtained an average total deformation of 5.0809e-012 m and the equivalent stress value with a maximum value of σ y, max = 0.20186 Pa. the results of the Ansys Static Structural simulation show that the average total deformation is 9.9275e-008 m.

T he simulation results using Ansys Fluent, shows the pressure contour with a maximum value of 198.424 Pa and Velocity streamline with a maximum value of 28.8669 m/s. T he 3D axial fan design is imported into the ANSYS Fluent, Static Structural, Modal and Harmonic Response software. While on the hub uses NACA 9312, 9412, and 9512 airfoils with angle variations of 20, 30, and 60 and simulated to find the value of vibration and stress analysis.

The experimental design used is using NACA 1412, 4142, and 6412 airfoils on the tip with variations in angles of 60, 74, and 80.

Airfoil fan software#

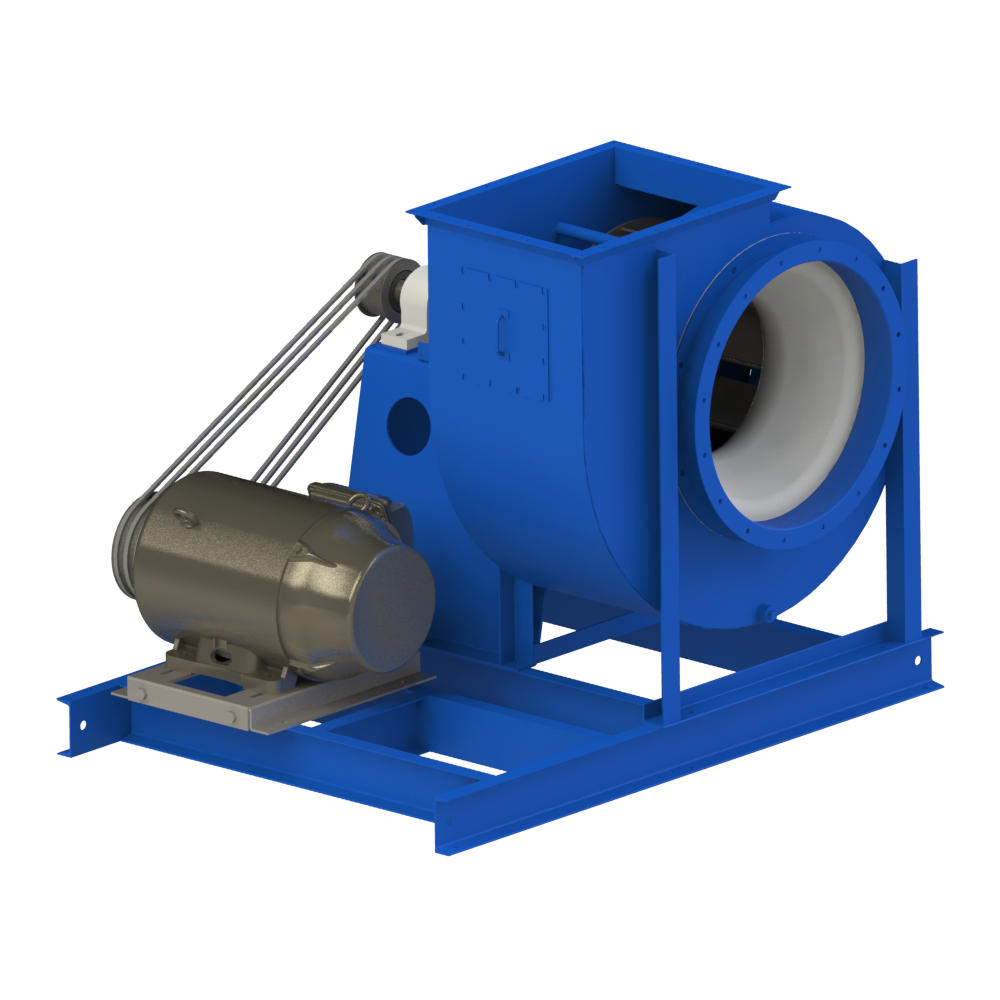

T his study performs axial fan analysis using computational methods with ANSYS Fluent, Static Structural, Modal and Harmonic Response software to obtain the values of stress, vibration and fluid flow. Unfortunately, there are not many articles that discuss in detail about airfoils, especially on noise and vibration that can have an impact on axial fan performance using computational fluid methods or software. T he blade design of the axial fan requires an airfoil study. Axial fans are used for ventilation systems and other cooling systems. Axial fans are widely applied in the industrial sector.

0 kommentar(er)

0 kommentar(er)